9.09.2025

These rigorous tests, involving a 10-parachute array and advanced materials, validate key safety systems, paving the way for the upcoming uncrewed mission and future crewed flights under the Gaganyaan Mission.

Gaganyaan crew module with the Indian Navy (File) | X/ ISRO

India’s ambitious human spaceflight programme, Gaganyaan, has crossed another critical milestone with the Indian Space Research Organisation (ISRO) recently undertaking rocket-sled trials at the Rail Track Rocket Sled facility in Chandigarh.

In these trials, the drogue parachute, responsible for stabilising and decelerating the crew module during re-entry, was tested in multiple scenarios. Partial deployment, full deployment, and steep-angle trials all yielded positive outcomes, proving the system’s reliability during critical recovery phases. As the December unmanned launch of the Gaganyaan mission kicks off, this test was critical.

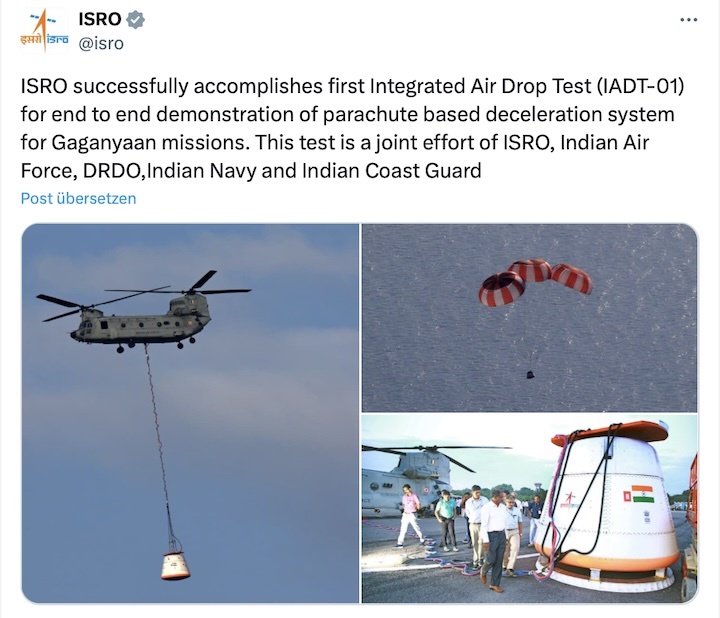

Recently, ISRO also conducted the Integrated Air Drop Test at the Satish Dhawan Space Centre, Sriharikota, where a 4.8-tonne crew module simulator was released from an Indian Air Force Chinook helicopter at an altitude of three kilometres. The parachute sequence unfolded in perfect order, beginning with the Apex Cover Separation system and followed by the drogue, pilot, and main parachutes, each triggered through mortars and pyrotechnics. The ten-parachute array gradually slowed the module to a survivable eight meters per second before splashdown, and the successful recovery carried out by the Indian Navy validated the entire end-to-end process.

“ISRO’s parachute tests represent a breakthrough in engineering precision and technological self-reliance, seamlessly blending indigenous innovation with international best practices. Conducted under demanding conditions, the trials confirmed the reliability of the intricate deceleration system that must safeguard astronauts during the violent re-entry and splashdown phases of the mission,” explained Srimathy Kesan, the founder and CEO of Space Kidz India.

Experts point out that these achievements demonstrate India’s ability to deliver solutions that are both world-class and cost-effective, setting new benchmarks in space technology. At the heart of these breakthroughs is a revolution in materials science.

The drogue parachutes, manufactured at the Ordnance Equipment Factory in Hazratpur, Uttar Pradesh, employ advanced Nylon 66 fabric with thermal resistance up to 250°C. The rigging lines, chords, and tapes are crafted from materials with melting points as high as 427°C, providing multiple layers of redundancy for maximum safety. Each parachute canopy requires around 5,000 hours of meticulous manufacturing, reflecting the precision demanded by human spaceflight. The shift from imported ripstop nylon to fully indigenous production not only reduces costs but also affirms India’s ability to match international quality standards while strengthening domestic industries.

The road to the first uncrewed mission, scheduled for December 2025, is carefully structured. ISRO will continue with additional integrated drop trials under varying wind conditions, orientations, and abort scenarios to strengthen robustness.

“The crew escape system, already demonstrated in the TV-D1 test, will undergo another high-altitude evaluation to confirm astronaut safety during emergencies. The human-rated LVM3 rocket, upgraded with the C-32 cryogenic stage, is being rigorously tested to achieve unprecedented levels of reliability, while the life support system, designed to maintain Earth-like conditions inside the crew module, will be validated with the humanoid robot Vyommitra onboard.

Avionics and telemetry systems are being refined to guarantee real-time accuracy in transmitting navigation, environmental, and health data, and recovery rehearsals with the Indian Navy, Coast Guard, and Air Force are underway to ensure rapid module extraction, medical triage, and crew transport procedures after splashdown,” added Kesan.

The parachute systems themselves reflect remarkable engineering, relying on multi-layered redundancy, advanced sequencing logic, and high-strength materials. Mortar initiation systems enable secure deployment at high G-forces, pyro-based releasers prevent entanglement during descent, and solid-state data recorders capture detailed test data for post-mission analysis.

The drogue parachutes, with a diameter of 5.8 metres, employ reefing mechanisms to manage stress, while the massive 25-metre main parachutes can collectively support 3,000 kilograms—though only two are needed for a safe landing, ensuring robust redundancy. Every component has been designed and produced in India, from textiles to rigging, underscoring the nation’s self-reliant approach.

“The mission architecture has evolved significantly since its inception. The Gaganyaan spacecraft will launch aboard a Human-rated Launch Vehicle Mark 3 (HLVM3) from the Satish Dhawan Space Centre.

The crew module integration reached a major milestone in January 2025 when the Liquid Propulsion Systems Centre successfully incorporated the Crew Module Propulsion System, a bi-propellant Reaction Control System featuring twelve 100-Newton thrusters for three-axis control,” remarked space analyst Girish Linganna.

The parachute system delivered by the Aerial Delivery Research and Development Establishment represents one of the most complex recovery systems ever developed by India. The ten-parachute configuration is designed for sequential deployment, beginning with the Apex Cover Separation parachutes that expose the drogue chutes, followed by pilot parachutes that extract the main parachutes for final descent and splashdown in Indian waters.

International collaboration has strengthened the mission's capabilities. In December 2024, ISRO and the European Space Agency signed a technical implementing plan providing ground station support for Gaganyaan missions. This partnership establishes uninterrupted data flow and communication with the mission's Orbital Module through the European Space Tracking network. Radio frequency compatibility tests completed in February 2025 confirmed seamless integration between Gaganyaan's onboard systems and European ground stations.

Before the December uncrewed mission, ISRO must complete several critical test phases. The Test Vehicle missions TV-D2, TV-D3, and TV-D4 remain essential components of the validation process. TV-D1, successfully completed in October 2023, demonstrated the crew escape system's capability to safely separate the crew module from the launch vehicle during emergency abort scenarios. The subsequent test vehicle missions will evaluate more complex abort scenarios and validate crew escape systems under varying flight conditions.

Additional ground testing includes thermal vacuum tests to simulate space environment conditions, dynamic and acoustic tests to ensure structural integrity under launch stresses, and comprehensive electrical system validations. The orbital module integration requires meticulous assembly of the crew module and service module, followed by extensive interface testing to ensure seamless communication between all subsystems.

Safety systems testing remains paramount, including validation of the Crew Module Uprighting System designed to prevent the capsule from overturning in rough seas. This system, resembling inflatable balloons similar to automotive airbags, addresses issues identified during the TV-D1 recovery when the crew module experienced unexpected orientation while being retrieved by the Indian Navy from the Bay of Bengal.

The CE-20 engine, powering the cryogenic upper stage of the HLVM3, has successfully completed all ground certification tests for human rating. These tests included life demonstration evaluations, endurance assessments, and performance evaluations under both nominal and off-nominal conditions regarding thrust, mixture ratio, and propellant tank pressure.

“Environmental control and life support systems require extensive testing to ensure astronaut safety during the mission. These systems must maintain Earth-like atmospheric conditions within the crew module, including proper oxygen levels, carbon dioxide removal, temperature control, and humidity management throughout the orbital phase,” pointed out Linganna.

December’s uncrewed mission with Vyommitra will serve as a global demonstration of India’s capabilities, validating every system in space before human lives are placed aboard. It will lay the foundation for future milestones: the Bharatiya Antariksh Station by 2035 and a crewed lunar landing by 2040. Each successful test, from parachute deployments to escape system trials, brings India closer to the historic moment when Gaganauts ascend to orbit on an indigenous spacecraft.

Quelle: THE WEEK