8.11.2019

ULA begins stacking unique Atlas 5 rocket for Starliner test flight

The stacking of a United Launch Alliance Atlas 5 rocket this week at Cape Canaveral signals the start of a busy six-week campaign to ready ULA’s trusty workhorse launcher for its debut in a new human-rated configuration in mid-December.

“There are certainly some unique and very exciting things about this particular vehicle,” said Caleb Weiss, ULA’s mission manager for the Starliner program.

The “firsts” for the Atlas 5’s next launch include the rocket’s first flight without a payload fairing, and the first use of a dual-engine Centaur upper stage on the Atlas 5. The Atlas 5 has flown 80 times to date, amassing a flawless success record carrying U.S. military, NASA and commercial payloads into orbit.

But launching astronauts comes with its own set of requirements, including new computers to monitor the rocket’s performance, and if required, trigger an abort to ensure the crew can escape the launcher in an emergency.

“Electrically, one of the unique things about this mission is that the launch vehicle and spacecraft are going to be talking to each other,” Weiss said in a recent interview. “We normally don’t have that. They will be sharing data throughout (the) flight.”

The Starliner spacecraft, developed by Boeing under a $4.2 billion commercial crew contract with NASA, will be the heaviest payload ever launched by an Atlas 5 rocket.

“I think it is absolutely more complex (than a typical ULA mission), and the reason is that, even though the mechanical interface may seem simple because it’s a bolted ring interface, to get to that bolted ring interface took a lot of design work and analysis to make sure that it could handle the flight loads,” Weiss told Spaceflight Now in an interview. “The aero skirt obviously has all the aerodynamic analysis behind it, and it also has doors in the bottom that will open in the event of an abort. That way, the abort engines have a place to vent so you don’t build up pressure in that cavity in an abort. So there’s certainly a lot of capability that’s built in just to the structure.”

ULA ground crews raised the Atlas 5’s first stage upright after sunrise Monday, and a crane carefully positioned the rocket on top of a mobile platform inside the Vertical Integration Facility at Cape Canaveral’s Complex 41 launch pad.

The milestone event, known as Launch Vehicle On Stand in ULA’s parlance, kicks off final assembly of the Atlas 5 rocket that will launch Boeing’s CST-100 Starliner crew capsule on its first space mission. The Starliner’s Orbital Flight Test, or OFT, is scheduled for liftoff Dec. 17 on an unpiloted demonstration of the ship before astronauts fly on the next Starliner spacecraft in 2020.

The Starliner spacecraft will fly in autopilot mode to the International Space Station for a week-long mission to assess the ship’s readiness for crewed flights. At the end of the mission, the capsule will undock and return to Earth for landing under parachutes — and cushioned by airbags — at one of several possible locations in the Western United States.

Boeing’s preferred landing site for the test flight is at White Sands Missile Range in New Mexico.

The Atlas 5’s 107-foot-long (32-meter) bronze first stage is powered by a Russian-made RD-180 engine that burns kerosene and liquid oxygen. On launch day, ULA will load 25,000 gallons of RP-1 kerosene fuel and 49,000 gallons of liquid oxygen into the first stage.

ULA plans to install two Aerojet Rocketdyne solid rocket boosters to the Atlas 5 core stage later this week, then lift the rocket’s Centaur upper stage atop the vehicle. Late last year, technicians mated the Centaur to the Atlas 5’s interstage adapter, which connects the Centaur with the first stage, and the launch vehicle adapter, the structural interface between the rocket and the Starliner crew capsule.

The Centaur, along with the adapters, will be raised at the end of the week on top of the Atlas 5 first stage in a single piece to complete the initial build-up of the launcher inside the VIF at pad 41.

Then comes a series of initial checkouts of the Atlas 5 rocket systems before Boeing’s Starliner spacecraft arrives at the launch pad in mid-November.

In mid-November, Boeing’s team will roll the Starliner spacecraft out of its factory, a former space shuttle hangar at NASA’s Kennedy Space Center, a few miles from the Atlas 5 launch pad.

With the addition of the Starliner capsule, the Atlas 5 rocket will stand 172 feet (52 meters) tall. That’s somewhat shorter than other Atlas 5 configurations, which fly with bulbous payload shrouds to shield satellites during the first few minutes of flight through the thick lower atmosphere.

The Starliner, with its thermal protection coating, does not require a payload fairing during launch.

This week, teams are loading several tons of hydrazine and nitrogen tetroxide propellant into the Starliner spacecraft inside a special fueling area inside the Boeing-run factory adjacent to Kennedy’s towering Vehicle Assembly Building.

Boeing technicians connected the two components of the Starliner spacecraft — the crew module and the service module — last month in preparation for the OFT mission.

After installing the Starliner on the Atlas 5, ULA and Boeing will roll the fully-assembled rocket to pad 41 for a full-up countdown rehearsal. The rocket will ride its mobile platform on rail tracks for the 1,800-foot (550-meter) trip to the pad.

The Integrated Day-of-Launch Test, or IDOLT, is a major exercise for ULA and Boeing ground teams.

The test “will give us the opportunity to deploy the crew access arm and verify all the access tower and arm interfaces with the spacecraft,” Weiss said. “We will fully tank the vehicle, and we will have people out there at the pad that will be simulating day launch operations, just like they will be for a real launch day.

“So they will be in the white room, they’ll open up the hatch of the Starliner,” he said. “They will practice going in and out, loading cargo, configuring Starliner for flight. So it’ll be a really good end-to-end system checkout of all the launch vehicle and spacecraft systems working together, as well as the people who are executing the operations.”

ULA constructed the crew access tower at pad 41 in preparation for Starliner launches. Near the top, a crew access arm provides astronauts with a walkway to board the crew capsule, with a “white room” to connect with the Starliner’s hatch.

Significant changes to the Atlas 5 rocket for crew missions include the Emergency Detection System, a computer that will track key parameters in flight, and command an abort if necessary.

The Atlas 5 carries two EDS processing units for redundancy. The rocket only needs one computer during launch.

The EDS processing units, based on the Atlas 5’s fight-proven INCA computer, will be “monitoring multiple measurements, thousands of times per second, up and down the rocket to look for anything that may appear off-nominal,” Weiss said. “And those boxes would be the ones to tell the spacecraft to abort if it ever detected something across the threshold.”

The EDS computers are located near the top of the Centaur upper stage. Data fed into the computers include “things like rates on the vehicle, accelerations, certain pressures, just various instrumentation across the vehicle that we chose as the critical measurements that could tell us if the vehicle is not performing nominally,” Weiss said.

Starliner’s unpiloted OFT mission will not have an active abort system. The capsule will be fitted with abort engines used during ground qualification testing, and engineers will evaluate the EDS computers’ performance to ensure proper settings for crewed missions.

On missions with astronauts, the Starliner crew could also manually issue an abort command using a handle inside the cockpit.

The Atlas 5’s first launch with the Starliner spacecraft will also be the first to employ a Centaur upper stage with two Aerojet Rocketdyne RL10 engines. The dual-engine Centaur stage previously flew more than 100 times on earlier Atlas rocket variants, most recently in 2004.

“That extra engine does provide the additional thrust to lift that heavy payload to LEO (low Earth orbit,” Weiss said. “It also lets us also let this fly as shallower trajectory, which is more favorable if we had to ever have an abort with the crew on there. So that additional trust lets us design the trajectory in a way that is that optimizes the safety of the crew.”

The RL10 engines will consume super-cold liquid hydrogen and liquid oxygen, cumulatively generating nearly 45,000 pounds of thrust.

ULA and Boeing developed a design fix in 2016 to address aerodynamic problems discovered during wind tunnel testing. A 70-inch-long (1.8-meter) aeroskirt extension is installed on top of the Centaur upper stage, where it will be positioned against the bottom of the Starliner spacecraft during launch.,

“We did have quite a bit of analysis that was done early on in the program, wind tunnel testing, and what that showed us was that really get optimal stability on the vehicle, we wanted to extend the aerodynamic surface of the spacecraft further aft and that’s where we came up with the 70-inch aeroskirt, “Weiss said. “So once we incorporated that change, we went back and did additional wind tunnel testing, and all that came back with an improvement — you can improve the aerodynamics and improve the stability, overall stability of the vehicle.”

The aeroskirt will jettison from the rocket shortly after the Centaur ignites its RL10 engines around five minutes after liftoff, around the same time a payload fairing separates during a standard Atlas 5 launch.

The demands of a crew mission also forced ULA’s launch team to adjust the Atlas 5’s countdown.

The Atlas 5 countdown typically lasts nearly seven hours for a satellite launch. For Starliner missions, the countdown will run nearly 11 hours.

Assuming the OFT launch date remains set for Dec. 17, the Atlas 5 will roll out to pad 41 on Dec. 15 to allow ground teams to configure the rocket for the countdown and sync their schedules for the launch.

For a Dec. 17 launch, the Atlas 5’s liftoff time will be approximately 7:45 a.m. EST (1245 GMT). The launch time is determined by space station’s orbit, and moves around 20 to 25 minutes earlier each day.

Fueling of the Atlas 5’s first stage and Centaur upper stage with cryogenic propellants will commence around six hours prior to liftoff. A built-in countdown hold at T-minus 4 minutes, which normally lasts 15 minutes, will extend for four hours, a change to give the astronauts time to board the spacecraft.

“We will count down all the way to T-minus 4 minutes,” Weiss said. “The vehicle is, at the point, where it is ready to launch, we’re about to enter terminal count, and then we’ll hold four hours. That point is made to make sure that we are safe and stable, that we’ve done everything on the rocket to get it into flight condition. We’re not having to do any other switch flipping or changes in configurations.

“We really want to be in that that flight condition when the crew goes out there because that’s the safest,” Weiss said. “That gives us time to review all the data, and ensure that we’re going to let the crew go out there only after the vehicle is verified safe.”

SpaceX, NASA’s other commercial crew contractor, will strap astronauts into the Crew Dragon capsule before fueling of the ship’s Falcon 9 booster. SpaceX argues its plan, known as “load and go,” is safer because ground teams will not be at the launch pad with the rocket fueled for liftoff, and the Dragon crew could escape from the Falcon 9 using the capsule’s abort engines in case of an emergency.

Boeing’s plan for strapping the crew into the Starliner spaceship mirrors the way NASA boarded astronauts during the Apollo and space shuttle programs.

A “blue team” comprised of fewer than 10 Boeing and ULA employees will help the astronauts into the Starliner spacecraft during countdowns for crewed missions. The team’s job will be similar to the closeout crew from the Apollo and shuttle eras.

During the OFT countdown in December, the blue team will travel to the launch pad and run through their launch day procedures during the four-hour countdown hold, just as they would if astronauts were flying, according to Weiss.

The blue team will close the Starliner hatch and evacuate the pad before the resumption of the countdown. The crew access arm will retract from the Starliner spacecraft less than 10 minutes before liftoff, Weiss said.

Then the countdown clock will start ticking again at T-minus 4 minutes, and the Atlas 5 will switch to internal power, pressurize its propellant tanks, and prepare for ignition of its RD-180 main engine.

For Starliner flights to the space station, the Atlas 5 will vector its engine nozzles to head northeast from Cape Canaveral, paralleling the U.S. East Coast. The flight path will align the Starliner’s ground track with that of the space station.

The Atlas 5’s two strap-on solid rocket boosters will burn out around 90 seconds into the mission, then release to call into the Atlantic Ocean.

The RD-180 engine will throttle back late in its four-and-a-half minute burn to limit acceleration loads on the Starliner — and its crew — to no more than 3.5 Gs.

The first stage will switch off its RD-180 engine and jettison around four-and-a-half minutes after liftoff, allowing the Centaur upper stage to fire its RL10 engines to accelerate the Starliner spacecraft to near-orbital velocity.

According to ULA, the Atlas 5 will release the Starliner spacecraft on a 112-mile-high (181-kilometer) suborbital trajectory, just shy of the velocity needed to enter a stable orbit around Earth. After separating from the rocket, the Starliner’s own engines, mounted on the ship’s service module, will boost the spacecraft into orbit to begin the trek to the International Space Station.

The suborbital trajectory is unusual for a satellite launch, but it is similar to the technique used by the space shuttle. The shuttle’s three main engines, fed by cryogenic propellants from an external fuel tank, accelerated the orbiter into space, reaching a velocity just short of that required to enter orbit.

After jettisoning the expendable external tank, the shuttles fired their in-space maneuvering engines around a half-hour after launch to enter orbit. Otherwise, the shuttles would have cut short their missions and re-entered the atmosphere.

The Starliner will follow a similar launch profile on the OFT mission, and on the subsequent crewed flights.

“The Atlas 5 is flying a very unique trajectory for us,” said Josh Barrett, a Boeing spokesperson. “ULA usually flies the Atlas 5 on a steep trajectory to use the powerful booster engine and any added solids to gain as much altitude as quickly as possible before leveling off and then letting the incredibly efficient Centaur push the rest of the way to the desired orbit.

“With Starliner, the Atlas 5 is flying a much flatter and throttled back trajectory for two main reasons,” Barrett said in response to questions from Spaceflight Now. “The first is if we abort on a steep trajectory, we would have the potential to bounce off the atmosphere, so this trajectory allows a safe abort at every point through ascent. The second is it helps keep g-loading on crew members to a minimum on ascent.”

Boeing demonstrated the Starliner’s abort system in a critical test Monday in New Mexico. Engineers are investigating why one of the capsule’s three main parachutes did not deploy as intended, but Boeing says the chute issue is not expected to impact plans to launch the OFT mission in December.

“All the elements are clearly coming together,” said Chris Ferguson, a Boeing astronaut and former space shuttle commander who will fly on the Starliner’s Crew Flight Test next year. “In the meantime, we’re building up Spacecraft 2, which will be the one that will be the Crew Flight Test article.”

Ferguson will be joined on the Crew Flight Test by NASA astronauts Mike Fincke and Nicole Mann. The astronauts will spend up to six months on the space station.

Assuming a successful Crew Flight Test, NASA will certify the Starliner to begin regular crew rotation missions to the station later next year. SpaceX is performing a similar series of tests, having completed a pad abort test in 2015 and an unpiloted demonstration flight — similar to Boeing’s OFT — in March.

“We have got a lot of moving parts right now with various teams all over the country pulling together to make this all happen, and get humans back into space from the East Coast of Florida very soon,” Ferguson said Monday.

Quelle: SN

----

Update: 21.11.2019

.

Boeing’s first space-ready Starliner crew capsule heads to its launch pad Thursday

Boeing’s first Starliner crew capsule to fly in space is set to depart its factory Thursday at the Kennedy Space Center in Florida for a trip to a launch pad a few miles away, where it will be raised atop an Atlas 5 rocket for liftoff next month on an unpiloted test flight to the International Space Station.

The Starliner spacecraft is being readied for liftoff no earlier than Dec. 17 from Cape Canaveral on a week-long unpiloted demonstration flight to the International Space Station, a crucial precursor before the first crewed Starliner mission next year.

Fresh out of a fueling cell inside a former space shuttle hangar at Kennedy, the Starliner spacecraft is scheduled to roll out of its manufacturing facility around 5 a.m. EST (1000 GMT) Thursday on a slow-speed transporter for a road trip to pad 41 at nearby Cape Canaveral Air Force Station.

The Starliner spacecraft will be hoisted by crane into the Vertical Integration Facility at pad 41, where ground crews will connect the capsule to the top of a United Launch Alliance Atlas 5 rocket.

ULA began assembling components of the Atlas 5 rocket inside the VIF on Nov. 4, when the Atlas 5’s first stage was raised vertical on top of a mobile launch platform. Since then, technicians have installed two strap-on solid rocket boosters on each side of the Atlas 5’s bronze first stage and lifted the rocket’s Centaur upper stage on top.

The Centaur upper stage features two major changes from hardware that’s flown on ULA’s 80 previous Atlas 5 launches.

The Centaur designed for Starliner missions is powered by two Aerojet Rocketdyne RL10 engines, while the earlier Atlas 5 missions flew with a single-engine Centaur stage. ULA also designed a structural skirt on the top of the Centaur stage to reduce aerodynamic loads during the rocket’s climb through the atmosphere, a change introduced because the Starliner will not fly inside a payload shroud during launch.

Since stacking the Atlas 5 rocket inside the VIF, ULA has powered up the launcher for a series of pre-flight checkouts. On Tuesday, ULA, Boeing and NASA teams conducted a mission dress rehearsal to practice countdown procedures ahead of the Starliner’s scheduled launch Dec. 17.

Once the Starliner spacecraft is lifted atop the Atlas 5, ground crews will verify a series of mechanical and electrical connections between the launch vehicle and the crew capsule. The entire Atlas 5 rocket with the Starliner on top will stand 172 feet (52 meters) tall.

NASA is paying Boeing more than $5 billion to develop, build and fly Starliner missions to ferry astronauts to and from the space station. SpaceX has received a similar set of agreements valued at approximately $3.1 billion for the company’s Crew Dragon spacecraft, which completed its first unpiloted test flight to the station earlier this year.

Both companies aim to fly NASA astronauts into low Earth orbit in the first half of 2020, ending nearly nine years of U.S. reliance on Russian Soyuz crew ferry ships since the retirement of the space shuttle.

Quelle: SN

----

Update: 22.11.2019

.

Boeing CST-100 Starliner Takes Next Step for Orbital Flight Test

By Linda Herridge

NASA's Kennedy Space Center

The Boeing CST-100 Starliner spacecraft that will launch to the International Space Station on the company’s uncrewed Orbital Flight Test for NASA’s Commercial Crew Program (CCP) has taken a significant step toward launch. Starliner rolled out of Boeing’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida on Nov. 21, making the trek on a transport vehicle to Space Launch Complex 41 at Cape Canaveral Air Force Station.

“This is critical to our future as a nation,” said Kennedy’s center director Bob Cabana. “We’ve got to get astronauts flying on U.S rockets from U.S. soil, and this is just a huge step forward.”

Cabana was joined by CCP and Boeing leaders in a gathering of employees and families to watch Starliner roll out of the factory.

“For the team that has built the first American spacecraft designed to land on land, and to get it rolling out, is absolutely incredible,” said John Mulholland, Vice President and Program Manager of Boeing Commercial Crew Programs. “Something this complex takes a huge team.”

“Look at that amazing sight and what your success looks like,” said Kathy Lueders, NASA’s Commercial Crew Program Manager. “We’re not done yet. We’ve got to step into the mission carefully, fly this vehicle up to the space station, and bring it home safely.”

At the pad, Starliner was hoisted up at the Vertical Integration Facility and secured atop a United Launch Alliance Atlas V rocket for the flight test to the space station. The Atlas V rocket that will carry Starliner comprises a booster stage and dual-engine Centaur upper stage, as well as a pair of solid rocket boosters.

NASA astronauts Mike Fincke and Nicole Mann and Boeing astronaut Chris Ferguson were on hand to witness the rollout milestone ahead of the uncrewed flight test.

“This is the dawn of a new era,” said Ferguson. “For all of you youngsters out there who came out here early to watch, I’m glad you were a part of this. This is really important because this is your future, too.”

“We’re looking forward to the day when we’re launching people on a regular basis,” said Fincke. “As graduates of military test pilot schools, we are really excited to see how Starliner’s going to behave; we know it’s going to be awesome, and we’re going to get all kinds of really great test data from it.”

The uncrewed flight test, targeted to launch Dec. 17, will provide valuable data on the end-to-end performance of the Atlas V rocket, Starliner spacecraft and ground systems, as well as in-orbit, docking and landing operations. The data will be used as part of NASA’s process of certifying Boeing’s crew transportation system for carrying astronauts to and from the space station.

“It comes down to trust,” said Mann. “I’m talking about trust in the individuals—our fellow Americans—who are building this spacecraft and making this possible. You walk around the factory and there is this amazing attention to detail, and it gives you this great level of confidence,” said Mann.

NASA is working in partnership with Boeing and SpaceX to launch astronauts on American rockets and spacecraft from American soil for the first time since 2011. Safe, reliable and cost-effective human transportation to and from the space station will allow for additional research time and increase the opportunity for discovery aboard humanity’s testbed for exploration.

Quelle: NASA

----

Update: 6.12.2019

.

ATLAS V TO LAUNCH STARLINER

• Rocket: Atlas V

• Mission: Boeing’s CST-100 Starliner, Orbital Flight Test

• Launch Date: Thursday, Dec. 19, 2019

• Launch Time: Under Review

• Launch Location: Space Launch Complex-41, Cape Canaveral Air Force Station, Florida

Mission Information: A United Launch Alliance (ULA) Atlas V rocket will deliver the CST-100 Starliner spacecraft to a 98 nautical mile (nmi) sub-orbital trajectory on its Orbital Flight Test (OFT) to the International Space Station. After Starliner separation from Atlas V, Starliner engines will burn taking it the rest of the way to orbit and on to the International Space Station.

Launch Notes: The Starliner Orbital Flight Test will be the 81st launch of the Atlas V and will mark ULA's 136th mission.

Launch Updates: To keep up to speed with updates, dial the ULA launch hotline at 1-877-852-4321 or join the conversation at www.facebook.com/ulalaunch, twitter.com/ulalaunch and instagram.com/ulalaunch; hashtags #AtlasV #Starliner

Go Atlas! Go Centaur! Go Starliner!

The AtlasV rocket with Starliner sits fully fueled at Space Launch Complex-41 for today’s countdown dress rehearsal ahead of the Orbital Flight Test mission.

Quelle: ULA

----

Update: 7.12.2019

.

Boeing's 1st Starliner Test Launch Now Set for Dec. 20 After SpaceX Dragon Delay

Boeing's first uncrewed test flight of its Starliner spacecraft for astronauts is now set for no earlier than Dec. 20, one day later than planned, due to a SpaceXlaunch delay earlier this week.

The United Launch Alliance (ULA) announced the 24-hour slip for Starliner today (Dec. 6) after successfully completing a critical "wet-dress" rehearsal for Boeing's upcoming test flight on an Atlas V rocket. During that rehearsal, Boeing, NASA and ULA fueled the Atlas V and practiced an entire launch countdown.

"We successfully conducted a wet dress rehearsal (WDR), a critical pre-launch milestone, on Friday, Dec. 6," ULA representatives said in a statement today. "We were unable to complete the milestone on Thursday, Dec. 5, as planned due to a weather-related launch delay of an International Space Station re-supply mission, which created a range resource conflict. This caused our targeted launch date to shift to the right by one day."

The resupply mission ULA refers to is SpaceX's CRS-19 Dragon cargo flight to the space station, which launched on Thursday (Dec. 5) after its own 24-hour delay due to high winds. A SpaceX Falcon 9 rocket launched the Dragon spacecraft from Space Launch Complex-40 at the Cape Canaveral Air Force Station, which is near ULA's Space Launch Complex-41, where the Atlas V carrying Starliner stands.

"We continue to work closely with Boeing to ensure that the Starliner flies as soon as the spacecraft and launch vehicle are ready," ULA representatives said.

Today's wet dress rehearsal — dubbed an Integrated Day of Launch Test, or IDOLT, in spaceflight jargon — included each step of the launch procedure right up until liftoff. The "wet test" paves the way for the capsule's Orbital Flight Test mission later this month, when the vehicle will make its way to the space station without astronauts aboard.

That flight, in turn, will prepare Boeing and the rest of the Starliner team for the first crewed flight of the vehicle, which is expected to take place next year, also on a United Launch Alliance Atlas V.

During the rehearsal, flight personnel fueled the rocket booster, then tended to the Starliner capsule itself, mimicking the process that will unfold when astronauts take their first flight.

All told, the test took about six hours to complete, bringing the procedure right up to T-0 in the launch countdown, although the engines did not fire.

NASA astronaut Mike Fincke, who will be flying on the first crewed Starliner mission, was in Boeing's mission control at Kennedy Space Center for the test. He will fly with Boeing astronaut Chris Ferguson (a former space shuttle commander) and NASA colleague Nicole Mann.

Quelle: SC

----

Update: 13.12.2019

.

NASA approves Dec. 20 Starliner test flight

WASHINGTON — NASA gave its approval Dec. 12 to proceed with the launch later this month of Boeing’s CST-100 Starliner commercial crew spacecraft on an uncrewed test flight to the International Space Station.

At the end of a Flight Readiness Review at the Kennedy Space Center, NASA officials approved plans to launch the Starliner on its Orbital Flight Test (OFT) mission on a United Launch Alliance Atlas 5 at 6:36 a.m. Eastern Dec. 20. A launch on that day would result in the spacecraft docking with the ISS a little more than a day later, remaining there for nearly a week before landing at White Sands Missile Range in New Mexico in the predawn hours of Dec. 28.

“I’m happy to announce we’re go for launch,” NASA Deputy Administrator Jim Morhard said in a media teleconference shortly after the review concluded.

Phil McAlister, director of commercial spaceflight development at NASA, said there was still some “standard open work” to complete ahead of that launch, as well as resolve two open issues. “We could move off the 20th, but right now the 20th is looking good,” he said.

Those open issues, said John Mulholland, vice president and program manager of Boeing’s commercial crew program, include finalizing a review by the ISS program to confirm the Starliner flying on the mission matches the previously approved design, as well as final “data loads” for the spacecraft. Both of those, he said, should be completed before the scheduled Dec. 20 launch.

In the meantime, launch preparations will continue, including a final cargo load into the spacecraft Dec. 14 and rollout of the Atlas 5 with Starliner to the pad at Cape Canaveral’s Launch Complex 41 on Dec. 17. Starliner will be carrying an anthropomorphic test dummy, nicknamed Rosie, that will be instrumented to measure the conditions astronauts will experience on the vehicle. “And, absolutely, as we approach the holidays, we will be bringing presents for the crew,” Mulholland added.

Assuming the launch does take place Dec. 20, the spacecraft would dock with the station at 8:08 a.m. Eastern Dec. 21, with undocking at 2:16 a.m. Eastern Dec. 28. The nearly week-long stay, Mulholland said, is driven primarily by the requirement that there be two landing sites in the western U.S. available on consecutive days for the landing, adding that the fact the landing will be taking place at night — 5:48 a.m. Eastern — is not an issue.

If the launch doesn’t take place during the instantaneous launch window on Dec. 20, there are backup dates reserved for Dec. 21 and 23. Should the launch not take place by Dec. 23, Mulholland said several other dates are available, including Dec. 25 through 28. “We have plenty of available launch opportunities as we look forward into December,” he said.

A successful OFT mission would allow Boeing and NASA to proceed with a crewed flight test with agency astronauts Mike Fincke and Nicole Mann, and Boeing test pilot Chris Ferguson, on board. That mission would be ready to launch in the “first part of 2020,” Mulholland said, but declined to be more specific about a potential launch date. “We’re hesitant right now to set the launch date until we get through a solid Orbital Flight Test and make sure we thoroughly review the data and understand anything we might need to do to support the Crew Flight Test,” he said.

Kathy Lueders, NASA commercial crew program manager, said that SpaceX would also be ready to fly a crewed flight test in early 2020, some time after an in-flight abort test of the Crew Dragon spacecraft currently scheduled for no earlier than Jan. 4. “They’re getting their spacecraft ready and launch vehicle ready for first quarter of 2020.”

While optimistic that Boeing and/or SpaceX will have commercial crew vehicles ready to carry astronauts in 2020, the agency remains in negotiations with the Russian state space corporation Roscosmos to obtain additional Soyuz seats to ensure NASA astronauts can remain on the station after current agreements on Soyuz seats expire in the fall of 2020.

“We don’t have a negotiation settlement yet, but certainly both parties are very interested in seeing us maintain our astronauts and their cosmonauts on the International Space Station,” NASA Administrator Jim Bridenstine said in a Dec. 10 interview.

“Building a rocket, building a spaceship is very, very difficult,” said Kirk Shireman, NASA ISS program manager, during the Dec. 12 media call when asked about the status of procuring additional Soyuz seats. “While we are definitely working very hard with Boeing and with SpaceX to fly off U.S. soil, we need to make sure that we have margin. The worst thing we could do is to rush those things, rush finishing these vehicles.”

Quelle: SN

----

Update: 18.12.2019

.

Launch Readiness Review Complete, Boeing Orbital Flight Test ‘Go’ for Launch

Teams from NASA, Boeing and United Launch Alliance are “go” for a launch following today’s launch readiness review ahead of the Orbital Flight Test mission to the International Space Station for NASA’s Commercial Crew Program.

Launch is scheduled for 6:36 a.m. EST Friday, Dec. 20, from Space Launch Complex 41 at Cape Canaveral Air Force Station in Florida.

Meteorologists with the U.S. Air Force 45th Space Wing continue to predict an 80% chance of favorable weather with the primary concerns for launch day are the Cumulus Cloud Rule and User Ground Winds violations during the instantaneous launch window.

At 2 p.m., NASA will host a prelaunch news briefing at Kennedy Space Center. Participants are:

- Kathy Lueders, manager, NASA Commercial Crew Program

- Joel Montalbano, deputy manager, International Space Station Program

- John Mulholland, vice president and program manager, Boeing Commercial Crew Program

- John Elbon, chief operating officer, United Launch Alliance

- Pat Forrester, astronaut office chief, Johnson Space Center

- Will Ulrich, launch weather officer, 45th Weather Squadron

Quelle: NASA

+++

Starliner test flight passes launch readiness review

KENNEDY SPACE CENTER, Fla. — Boeing’s CST-100 Starliner spacecraft passed another in a series of final reviews Dec. 17 as it proceeds towards a critical uncrewed test flight.

NASA announced the Orbital Flight Test (OFT) mission passed a launch readiness review Dec. 17, five days after a separate flight readiness review. Officials with both Boeing and launch vehicle manufacturer United Launch Alliance said the review uncovered no issues that would prevent a launch on Dec. 20 at 6:36 a.m. Eastern.

“We are tracking no spacecraft anomalies right now,” said John Mulholland, vice president and program manager for Boeing’s commercial crew program, at a press briefing here. “The spacecraft is in really good shape.”

If no new technical issues arise and weather cooperates — the latest forecast projected an 80% chance of acceptable weather at launch time — the Atlas 5 carrying Starliner will lift off shortly before sunrise Dec. 20. The flight will be the first for the Atlas 5 that uses a dual-engine Centaur upper stage and the first without a payload fairing.

That choice of upper stage is driven by the trajectory needed for Starliner’s future crewed flights. “The main reason for using the dual-engine Centaur is to flatten out the trajectory such that we can enable safe aborts if that should be necessary,” said John Elbon, chief operating officer of ULA. That reduces the g-forces should an abort and reentry be required, and also avoids a “blackout zone” in the north Atlantic.

The Atlas 5 will place Starliner into a suborbital trajectory, with an apogee of 181.5 kilometers and a perigee of just 72.8 kilometers. Starliner’s thrusters will then circularize the orbit and begin the maneuvers needed to reach the International Space Station.

Starliner will arrive at the ISS about a day after launch, with docking scheduled for 8:08 a.m. Eastern Dec. 21. Besides an anthropomorphic test dummy, nicknamed “Rosie,” the Starliner will carry about 270 kilograms of cargo for the station, said Joel Montalbano, deputy manager of the ISS program at NASA. Most of that is food, but the cargo also includes some crew clothing and radiation-monitoring equipment.

Starliner will remain on the station until early Dec. 28, undocking at 12:44 a.m. Eastern and landing at White Sands Missile Range in New Mexico about five hours later.

The Starliner that is flying the OFT mission is “nearly identical” to the spacecraft that will be used for the later crewed test flight, Mulholland said, with the major differences being a launch abort system that will be in passive mode for this flight and a lack of an emergency oxygen system since no astronauts will be on board to test it.

Despite the similarities, and the optimism expressed by NASA and Boeing officials about the OFT mission, they declined to estimate when that crewed test flight will take place even if there are no issues with the OFT flight. Kathy Lueders, NASA commercial crew program manager, said the factors that drive the schedule for the crewed flight include reviewing all the data collected during OFT and working through the various reviews and certifications for the crewed flight.

“John [Mulholland] and I are still working through those schedules and finalizing those,” she said. “Having this demonstration mission is going to be a key part of that schedule.”

Elbon said ULA was in discussions with Boeing about potential launch dates for that crewed flight, working around other Atlas 5 launches that have tight launch windows, like the Solar Orbiter mission launching in February and Mars 2020 in July.

“I think there’s a couple areas we can fit in on the manifest in that first part of the year,” Mulholland said. “We really wanted to stay away from any announcement of a Crew Flight Test launch date until we successfully complete OFT and we’re ready to lock in a launch date.”

Quelle: SN

----

Update: 19.12.2019

.

Starliner launch team driven by challenges, committed to safety

When Boeing design engineer Melanie Weber watched the movie "Apollo 13" as a teenager something struck a chord.

“It was the triumph over challenges that’s so inspiring,” Weber said

Years later she turned that inspiration into a career helping design Boeing’s Starliner spacecraft.

“As an engineer I just love that. I like the challenges, the ‘Hey, this isn’t working. How am I going to make this work? This cannot be hopeless. There has to be a solution and I think I can find that solution.’ I love being pushed and that’s what drives me to come to work every day.”

The Starliner's first ever orbital flight test is scheduled for Friday morning at 6:36 am Eastern aboard an Atlas V rocket from Launch Complex 41 at Cape Canaveral Air Force Station.

One of her biggest tasks was figuring out how to make seats that can accommodate both female and male astronauts who range from the 5th percentile in stature to the 95th percentile in stature.

"Designing a seat that can accommodate all anthropometric ranges was probably one of the biggest challenges I ever had.” Weber said.

The solution was to create custom 3D molded inserts that is integrated into the seat.

“We actually scan each crew member, we scan their backs, and we have 3D printed seats, basically the adapter that goes between the structure of the seat to hug them for launch and reentry,” Weber said.

During this process Weber worked closely with the astronauts and developed a close relationship with them particularly commander Chris Ferguson.

“We work really well together. We’ll joke around with each other — I need to make sure that he’s comfortable with me so that he can tell me the hard things: what he’s worried about, what he’s scared about.”

It wasn't long before Weber was asked to be the launch pad lead. Her knowledge of the spacecraft and connection to the astronauts made her a natural for the critical position. The pad lead is the last person to see the astronauts before the hatch is closed and she gives the all-clear to mission control.

“I want them to trust me. I want to make sure that they’re not nervous or scared so that when we go to day of launch that their training kicks in and they’ve got nothing to worry about because I’m there. I got you. You’ve got this, we’ve got this. We’re gonna get you in and this is gonna be awesome, enjoy the ride.”

She’s also the first female and first Hispanic to perform the duty.

“I really hope that because I am in that position that there is another Hispanic woman that says ‘Yes, I can do that because she did it.’ I really hope I can be that breakthrough,” Weber said.

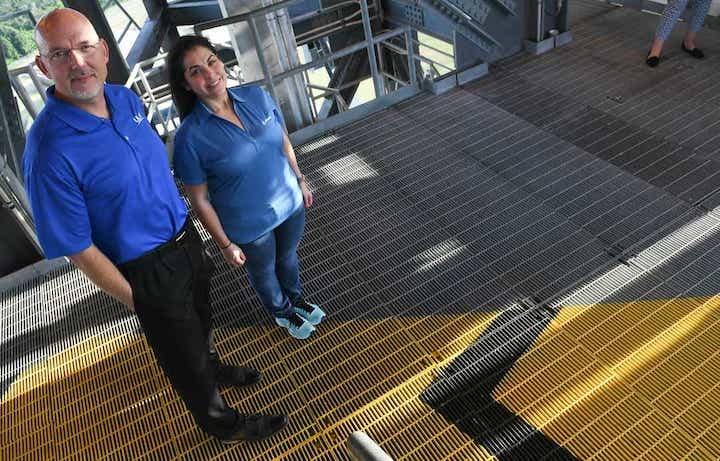

Of course behind every great pad team lead is a launch tower lead. Dane Drefke works for United Launch Alliance the company that makes the Atlas V rocket that will launch Starliner and oversees the tower at Launch Complex 41 at Cape Canaveral Air Force Station. Drefke and his team are responsible for the “white room” at the top of the tower where the astronauts enter the spacecraft.

“I’m kind of the traffic cop. I’m the one who coordinates the movements of all the people who come in and out of the white room and prepare the spacecraft to receive the astronauts,” Drefke explained.

After 25 years working in the space industry, Drefke is elated to be working on a program that will launch humans to space.

“That is a dream come true because I was a child of Apollo and grew up watching the astronauts getting into the capsule,” Drefke remembers. “I wanted to be an astronaut but it didn’t happen so I’m doing the next best thing.”

Drefke and Weber work hand in hand toward a singular goal: to safely launch humans to space.

“What people don’t understand is that rockets are extremely unforgiving. You get one chance to get it right. When it leaves the ground it’s gotta be a 100% right so we make sure everything is to the best of our knowledge and best of our ability 100% correct,” Drefke said.

The Starliner orbital flight test on Dec. 20 is the final test to make sure they have everything right. On this flight to the Internal Space Station, an anthropometric test dummy outfitted with sensors will be standing in for the astronauts but Weber is already thinking about the day that her colleagues will be strapping in.

“I’m already prepping myself for that day of launch when they’re there and maybe think about what I need to say if I feel like they’re getting nervous and how I can calm them down and reassure them that they have nothing to worry about.”

Weber still has a few months to figure that out. For now, her mind and heart is focused on Friday morning’s launch.

“That moment we finally get that ‘we’re go for launch’ and finally hear T minus zero and feel the engines go and see the vehicle rise about the tree line and clear the tower is going to be a momentous occasion for the entire team.”

Quelle: Florida Today

+++

How to watch Boeing Starliner launch on Atlas V rocket from Cape Canaveral

Friday's the day.

After years of planning, development and building, 6:36 a.m. will be the moment a United Launch Alliance Atlas V rocket launches Boeing's Starliner, a capsule that will eventually take astronauts to the International Space Station.

Friday's flight is an uncrewed test of the capsule, known as Orbital Flight Test, that will see