28.01.2019

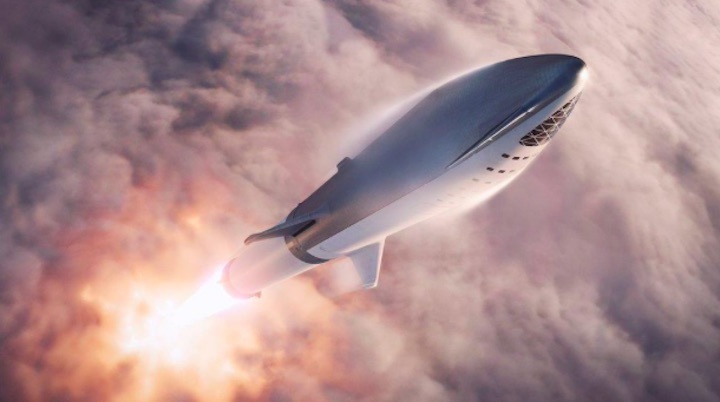

SpaceX workers cap Starship with tank dome as Raptor arrivals and hop tests near

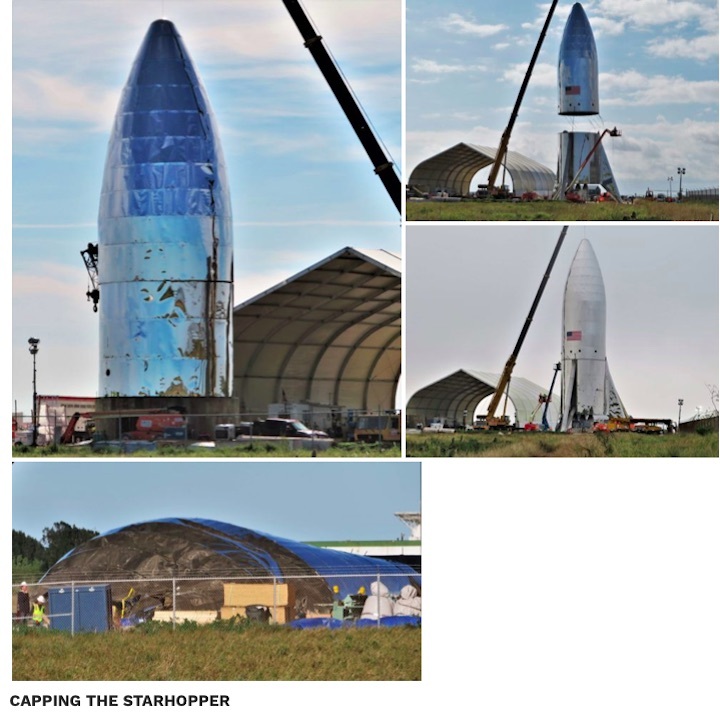

SpaceX employees and local contractors continue to outfit the aft section of the first full-scale BFR prototype with a variety of important components, recently culminating in the installation of the Starship hopper’s top propellant tank dome,

Critical to the arrival and installation of its Raptor engines and the craft’s first hop tests, this work continues despite the premature demise of Starhopper’s apparently fragile nose cone (fairing), toppled on January 22nd when fairly mild winds of around 50 mph (80 km/h) encountered the shoddy rigging meant to keep the huge but lightweight hardware on its concrete stand.

As photos and the media fervor that ensued generally illustrate, the nose section certainly was not effectively held to its concrete stand, causing the insufficient rigging to break and the large sheet metal structure to unceremoniously collapse and fold in half under its own weight. While 50 mph (90 km/h) gusts are not insignificant, they are also fairly common, especially when located on the unprotected edge of the South Texas Coast in the middle of the winter.

Put in a slightly more direct fashion, building a complex structure outside without ensuring that it will be able to withstand the region’s average inclement weather would be an embarrassing oversight for even the most basic construction project, no less SpaceX’s first Starship prototype. It’s also possible that local construction contractors are being leaned on to complete an aerospace-ish project they would likely have little practical experience with, in which case run-of-the-mill workplace miscommunication or a failure to double-check work (rigging) could have easily led to the fairing’s demise.

Regardless, what is done is done and whatever lessons were learned the hard way will hopefully prevent a repeat and encourage better workmanship throughout the project.

With the crumpled fairing section now beginning repairs under SpaceX’s lone on-site tent, SpaceX workers and contractors got back to the (available) tasks at hand and took another step towards Starhopper’s completion, installing the craft’s topmost propellant tank dome and effectively ‘capping’ the most important segment of the prototype.

Recently described by SpaceX CEO Elon Musk as a “fairing”, the upper section of Starhopper can presumably be compared with Falcon fairings, while the aft half – to feature two common-dome propellant tanks and an engine section with three Raptors – is likely roughly equivalent with Falcon 9 or Falcon Heavy boosters. For Falcon, fairings are dramatically less valuable than boosters (or upper stages) and far easier to produce. Aside from a collection of holes cut around its base, the nose section does appear to be more of an aerodynamic cap than anything with an active function, lending some credence to Musk’s claim that it “will take a few weeks to repair.”

After capping Starhopper’s tank and engine section, additional tank segments continued to be craned inside the aft section through the top dome’s large header gap, presumably allowing workers to finish up work while the craft is quite literally built around them, an undeniable method of saving time.

Up next, the most obvious milestone for Starhopper will be the static firing of its Raptor engines at SpaceX’s McGregor, Texas test facilities, followed soon after by the delivery of the first flight-worthy engines to Boca Chica for installation on the Starship prototype. Given Musk’s January 5th estimate that SpaceX was 4 to 8 weeks away from the first hop test and the Jan. 23rd addition of “a few weeks” to repair the craft’s nose section, it’s probably safe to expect Starhopper’s first hop tests to begin no earlier than (NET) mid-March. This should also give construction workers a welcome influx of time to complete the Falcon 9-class hopper’s first rough launch pad.

Quelle: TESLARATI

----

Update: 2.02.2019

.

In new Starship details, Musk reveals a more practical approach

Goal is "to reach the Moon as fast as possible."

On Thursday night, SpaceX founder Elon Musk shared photos of Raptor rocket engines that recently left the company's factory in Hawthorne, Calif., headed out to be tested at its facility near McGregor, Texas. "Preparing to fire the Starship Raptor engine," he said by way of a caption on Twitter.

The photos were interesting, but Musk had additional comments about the engine that revealed much about how the company is proceeding with overall design of the vehicle it will power. SpaceX's approach seems focused on keeping costs down and moving as quickly as possible towards a launch of the Starship spacecraft and Super Heavy rocket in the early 2020s.

For example, Musk said, "Initially making one 200 metric ton thrust engine common across ship & booster to reach the Moon as fast as possible. Next versions will split to vacuum-optimized (380+ sec Isp) & sea-level thrust optimized (~250 ton)."

This comment is notable for a couple of reasons. First of all, the company appears to have decided to streamline the Raptor engine to a single design that will power both the rocket at liftoff, and the spaceship in the upper atmosphere and outer space. It will take less time to develop, test, and qualify a single engine. It will also cost less money.

Additionally, Musk notes that the goal is "to reach the Moon as fast as possible." The company still appears to be focused on lunar orbital flights, such as the #dearMoon project for Japanese businessman Yusaku Maezawa, as the first missions for Starship.

There is an added benefit to this approach: for the next two decades, NASA appears likely to be highly interested in developing infrastructure near and on the Moon. By flying Starship on early test flights to the same destination, SpaceX has a far greater chance to win government contracts for the delivery of cargo, and potentially astronauts, to the Moon. Heretofore, neither NASA nor the US military has shown much if any interest in SpaceX's ambitious rocket and spacecraft.

Cost concerns

In his series of tweets Thursday night, Musk shared other details that indicate he is intent on getting Starship flying as soon as possible. For example, initial versions of the Super Heavy rocket will likely fly with fewer than 31 engines, and the launch system's reaction control thrusters will have a simpler design.

These moves indicate that SpaceX and Musk are reacting to external pressures, particularly of a financial nature. Aside from the Japanese investor, it has not revealed any customers for Super Heavy and Starship, so the company is pressing ahead with a build-it-and-they-will-come approach to users. To accomplish this, however, it must cut costs elsewhere, as evidenced by the 10 percent reduction in workforce in January.

Musk reinforced this on a Jan. 30 Tesla investors' call, when he was asked whether recent layoffs at the automaker and SpaceX indicate a weakening economy. As part of his answer, Musk noted the need for tightening the belt at SpaceX as it embarks upon the high-cost development of the Starship and satellite-internet Starlink projects.

"We have to be super hardcore about it," he said regarding keeping headcounts down. "SpaceX has two absolutely insane projects that would normally bankrupt a company, Starship and Starlink, and so SpaceX has to be incredibly spartan with expenditures until these programs reach fruition."

To keep the pain to a minimum, SpaceX will push those programs to fruition as rapidly as possible. If that means the company's "Mars rocket" won't quite be in its final form, or even going to Mars, trips to the Moon can eventually fund missions to the red planet. Idealism is great and all, but engineers work best in the real world.

Quelle: arsTechnica

----

Update: 11.02.2019

.

SpaceX’s Starship engine breaks Russian rocketry record held for two decades

SpaceX CEO Elon Musk says the company’s Raptor engine, meant to power Starship and Super Heavy, has surpassed a rocketry record held by Russian scientists and engineers for more than two decades.

Known as combustion chamber pressure, Raptor has reportedly surpassed a modern Russian engine known as the RD-180, reaching forces equivalent to one Tesla Model 3 balanced on every square inch of Raptor’s combustion chamber, the hardware directly adjacent to a rocket engine’s bell-shaped nozzle.

First and foremost, it’s far too early to actually crown Raptor as the new official record-holder for combustion chamber pressure. RD-180 has been reliably flying on ULA’s Atlas V rocket with chamber pressures as high ~257.5 bar (3735 psi) since the year 2000, while Raptor has been performing subscale integrated testing for roughly two years and full-scale integrated testing for less than seven days. As such, the fact that full-scale Raptor has achieved ~269 bar (3900 psi) is an almost unbelievably impressive achievement but probably shouldn’t be used to jump to any conclusions just yet.

Thanks to the 10-20% performance boost supercool liquid methane and oxygen will bring Raptor, currently stuck using propellant just barely cold enough to remain liquid, the engine performing tests could already be made to reach its design specification of 300+ bar (4350+ psi), although Musk cautioned that he wasn’t sure Raptor would be able to survive that power in its current iteration. Nevertheless, 250 bar is apparently more than enough to operate Starship and its Super Heavy booster during most regimes of flight, although maximum thrust (and thus max chamber pressures) is probably desirable for the first minute or so after launch when gravity losses are most significant.

Ultimately, the sheer speed of SpaceX’s full-scale Raptor test program is easily the most impressive and encouraging aspect of the brand new engine design. While SpaceX does tend towards testing to destruction over putting on kid-gloves around flight or development hardware, it’s safe to say that even SpaceX would avoid frivolously destroying the first full-scale Raptor after just a few dozen seconds of integrated hot-fire testing, indicating that no major red flags have cropped up since the company’s propulsion team began testing on February 3rd. In fact, Musk estimated that six separate static-fires have been performed with Raptor in the seven days since its first ignition.

As of 2017, Raptor’s McGregor, Texas test cell was fundamentally capped at test durations under 100 seconds, making comparisons difficult. Still, the best possible recent point of comparison to Raptor’s test program can be found in NASA’s series of tests of Space Shuttle engines in preparation for the Space Launch System (SLS) rocket, an expendable launch vehicle being built by Boeing, Aerojet-Rocketdyne, NGIS (formerly Orbital-ATK), and others with NASA funds. Known as RS-25 under the SLS Program, the Space Shuttle engines being test-fired by NASA have already performed multiple full-duration missions to orbit and back on the four Space Shuttle orbiters built. After half a decade in storage, they are being re-tested (effectively acceptance testing) to ensure that they are ready to be expended on SLS launches.

In the first round of 2015 tests, NASA’s Stennis Space Center test stage supported six RS-25 static-fires total, ranging from two weeks to almost five months between tests. RS-25 testing has remained on a similar schedule in 2016-2018, averaging 4-6 tests annually with no fewer than two weeks between static-fires. Given that the vast majority of those ex-Space Shuttle Main Engine tests tend to last hundreds of seconds, it’s not a perfect comparison, but it offers at least a general idea of just how incredible it is to see a groundbreaking engine like Raptor test-fired almost daily just days after it was installed on a test stand for the first time.

Quelle: TESLARATI

----

Update: 18-02.2019

.

SpaceX job posts confirm Starship’s Super Heavy booster will be built in Texas

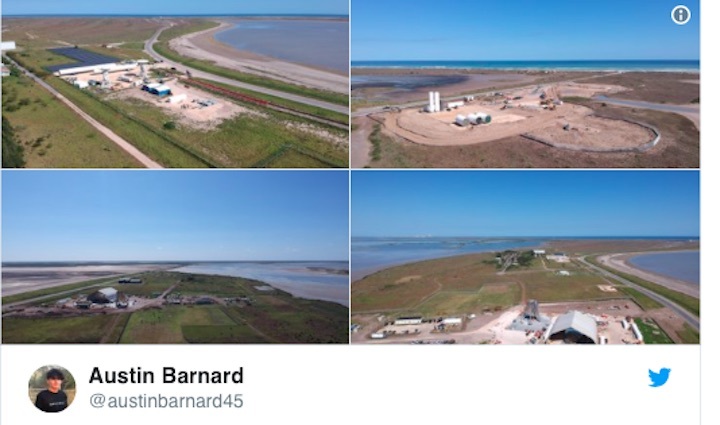

A duo of SpaceX job postings at the company’s South Texas facilities have confirmed that both Starship and Super Heavy “flight article” vehicles will initially be fabricated and assembled on-site in Boca Chica, also implying that the rocket’s first orbital launch attempts will occur in the same vicinity.

Construction of the first massive Super Heavy booster could begin in Boca Chica within the next several months, presumably progressing in a similar fashion to Starship’s full-scale hopper prototype. According to CEO Elon Musk, Starhopper hop tests and Super Heavy construction could begin – respectively – as early as March and April 2019, perhaps just one or two months from now.

WHERE TO BUILD A GIANT ROCKET?

“Tank fabricators will work to build the primary airframe of the Starship and Super Heavy vehicles at the SpaceX South Texas build site. [They] will work with an elite team of other fabricators and technicians to rapidly build the tank (cylindrical structure), tank bulkheads, and other large associated structures for the flight article design of both vehicles.” – SpaceX, 02/15/19

Posted on February 15th, both open positions centered around structural assembly (i.e. welding) critical for the construction of the massive propellant tank domes, barrel sections, and other major structure of Starship and Super Heavy. Following an unanticipated pivot to stainless steel – rather than advanced carbon composites – as the primary structural material of choice for BFR, the project has been continually marked by a flurry of impressive technical progress at the same time as many previously foundational aspects became uncertain.

Most notably, SpaceX appeared to terminate a lease agreement it had held with the Port of Los Angeles for a large berth meant to be developed into a dedicated factory for BFR’s massive spaceship upper stage and booster, whose 9m (~30 foot) diameter would have been highly impractical to build somewhere that wasn’t either at the rocket’s launch site or directly adjacent to a port. With its headquarters in Hawthorne, CA (southwestern Los Angeles), SpaceX’s first choice was unsurprisingly the Port of LA, a location that would have allowed its 5000+ local employees to have seamlessly transferred to the BFR program without requiring highly disruptive relocations.

Known as Berth 240, SpaceX’s lease began in March 2018 but was reportedly terminated in January 2019, likely meaning that the company will have to vacate the premises next month. While an official SpaceX statement and subsequent Elon Musk tweets relating to that report served to partially correct the record and confirm that “Starship prototypes” would be built locally in South Texas, Super Heavy was never mentioned. SpaceX’s latest job postings complete the image, indicating that all aspects of the first Starship and Super Heavy prototypes will be assembled in South Texas.

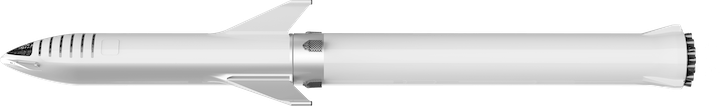

Weighing just shy of 4.5 million kilograms (~10M lbs) fully-fueled and standing around 118m (387 ft) tall with both stages stacked together, BFR is a beast of a launch vehicle and will require wholly new methods of production and assembly thanks to its sheer scale and the extensive integration of stainless steel alloys into its design. Compared to SpaceX’s Falcon 9 rocket, which is by no means small, Super Heavy on its own could end up being 68m (224 ft) tall, just slightly shorter than a complete Falcon 9 with a booster, upper stage, and fairing (71m, 233 ft). Standing on its tripod fins, Starship stands around 55m (180 ft) tall, although all of these figures are liable to change, as they come from a September 2018 SpaceX presentation that occurred before Musk publicized the move to stainless steel.

Likely to remain unchanged is the diameter of Starship and Super Heavy: 9m (30 ft), roughly 2.5 times wider than Falcon 9’s booster and upper stage. Even more true for a 9m-diameter rocket also meant to rely on a partial implementation of stainless steel balloon tanks, transporting Starship and Super Heavy more than a few thousand feet horizontally is going to be an extraordinary challenge, although SpaceX’s Boca Chica facilities are conveniently located just a mile or less from the Gulf of Mexico. While road transport is entirely out of the question, Saturn V’s massive first and second stage boosters proved to be relatively easy to transport thanks to the production facility being directly adjacent to a large body of water (or a river to get there, in their case).

“For all their prodigious bulk, [Saturn V’s 33.0 ft (10.1 m) diameter first and second stages] could be transported with comparative ease via seagoing barges [from Michoud, Louisiana to Cape Canaveral, Florida].” – Roger Bilstein/NASA, p. 301

Assuming SpaceX chooses to assemble Super Heavy with the same vertical, outdoors approach, Boca Chica, Texas is going to be greeted by a view even more exotic than the already-impressive progress being made with Starship’s Starhopper prototype. CEO Elon Musk noted that he believed the first Super Heavy prototype would begin to be built this spring (as early as April). In the meantime, SpaceX continues to exploit the benefits of stainless steel whenever it can, utilizing the company’s wealth of Hawthorne, CA expertise and infrastructure to fabricate subassemblies that can easily be shipped by road or plane to South Texas. After arrival, Boca Chica-based employees or contractors can be tasked with the considerably less infrastructure-intensive work of final assembly and integration, a challenging and critical process but one that is at least slightly more setting-agnostic.

SpaceX’s propulsion team continues to test the first full-scale Raptor engine a few hundred miles north of Boca Chica while Starhopper is gradually outfitted with a range of avionics, wiring, and plumbing needed for the vehicle’s hop test debut. That could come as early as March, according to Musk, although further delays should come as no surprise.

Quelle: TESLARATI

----

Update: 12.03.2019

.

SpaceX next-gen Raptor rocket engine is about to meet Starship in Texas

Starship and Raptor will soon be best friends as they get ready to shoot for the moon.

SpaceX might be hot off its triumphant NASA test flight of the Crew Dragoncapsule to the ISS, but Elon Musk's company is still looking toward the moon and Mars.

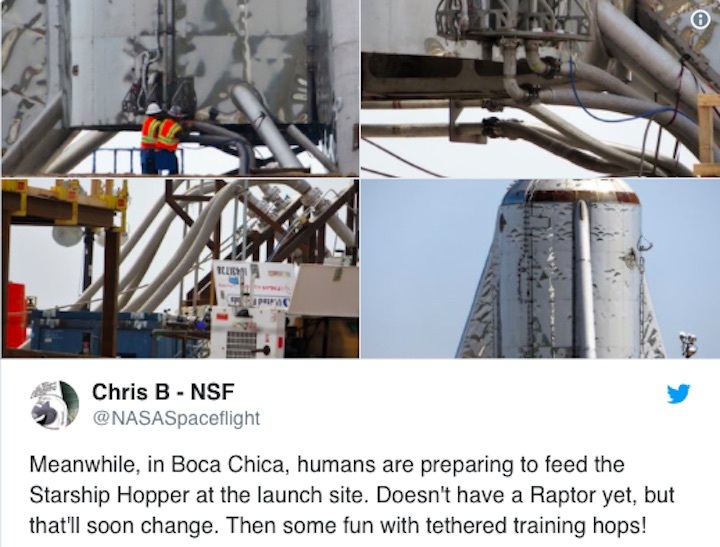

SpaceX's next-gen Raptor rocket engine just popped up in Texas, where the stainless-steel Starship prototype is located.

A Texas resident named Mary (who goes by bocachicagal) has been documenting the goings-on at SpaceX's Boca Chica Village launch site. She snapped a photo of the uncrated Raptor engine on Monday and shared it on the NASASpaceFlight.com discussion forum.

Musk teased the engine's arrival last week, saying the hardware was on its way to the "hopper" ship, which will be used to test takeoffs and landings. The SpaceX founder expects the Raptor will be mounted to Starship sometime this week.

Raptor on way to Hopper. Will be mounted to vehicle next week.

— Elon Musk (@elonmusk) March 8, 2019

First up will be a short static fire test of the engine, The Brownsville Herald reports. The vehicle will be tethered and the tests won't be visible to the public.

Some recent images of the hopper prototype without its elongated nose cone section appeared on NASASpaceFlight.com, so it looks like the first tests may not include the nose. High winds in January knocked the top section off of the Starship.

Starship is designed to pair up with SpaceX's Super Heavy rocket, which is currently under development. Musk said the rocket could use up to 31 Raptor engines, but initial flight tests would involve fewer engines in case it blows up. Starship itself can accommodate seven Raptor engines.

Musk recently shared video footage in February of a Raptor test firing, saying the engine had achieved the power level needed for Starship and Super Heavy. SpaceX hopes to use the combination to send tourists around the moon as early as 2023.

Quelle: Cnet

+++

SpaceX’s Elon Musk says Raptor will be installed on Starship prototype this week

Speaking on Friday, March 8th, SpaceX CEO Elon Musk announced that the company’s second completed Raptor engine was already “on [its] way to [Star]hopper” to – nominally – be installed on the prototype vehicle as early as the week of March 11th (this week).

According to an official SpaceX statement, once Raptor is installed on Starhopper, the integrated vehicle will perform a combination of ground systems testing, propellant loading, static fire tests, and low-altitude hover demonstrations to prove out the brand new vehicle, engine, and facilities. Prior to the final months of 2018, the build site, launch pad, and prototype Starship now preparing for imminent hop tests were little more than empty dirt lots on the southern tip of the Texas coast.

“SpaceX will conduct checkouts of the newly installed ground systems and perform a short static fire test in the days ahead,” he said. “Although the prototype is designed to perform sub-orbital flights, or hops, powered by the SpaceX Raptor engine, the vehicle will be tethered during initial testing and hops will not be visible from offsite. SpaceX will establish a safety zone perimeter in coordination with local enforcement and signage will be in place to alert the community prior to the testing.” – James Gleeson, March 8th, SpaceX

Prior to February 3rd, barely one month ago, SpaceX’s next-generation Raptor engine had yet to even ignite in its final(ish), full-scale form. Less than two weeks after that, SpaceX’s propulsion team had pushed the engine to the point of damage, quite possibly throttling it above its nominal max thrust and main combustion chamber pressures. According to Musk, Raptor serial number 2 (SN02) will feature moderate changes to mitigate the cause of that damage.

Along the path to hop tests, it’s unclear if Raptor SN02 – following the mild problems more or less intentionally forced upon its predecessor – will be test-fired at SpaceX’s McGregor, Texas development facilities before heading south to be installed on Starhopper. Given SpaceX’s methodical approach to engine and vehicle testing prior to the launch of any of its rockets, chances are good that it will have already conducted a number of basic acceptance tests in McGregor. If Musk is to be taken literally, the second flightworthy engine may already be in Boca Chica, although it’s more likely that it’s simply close to shipping there from either Hawthorne or McGregor.

It has not yet been confirmed if Starhopper will initially perform static fire and hop tests with just one Raptor installed, but the sheer power of the fairly compact engine (upwards of 200 metric tons or 450,000 lbf of thrust at full throttle) should more than enable an extremely heavy prototype to lift off even with 50+ metric tons of propellant onboard. While it could simply be a matter of convenience and efficiency to start integrated Starhopper testing immediately instead of waiting for the completion of additional Raptor engines, the process of testing a thrust structure or integrated rocket with an increasing number of engines installed is a relatively common practice in aerospace. Regardless of its history, SpaceX itself also began its first integrated testing of a Falcon 9 first stage in the same way, starting with one Merlin engine installed and ultimately graduating to 3, 5, and the final 9 engines over the course of a few months of testing.

While Starhopper is unlikely to need more than a handful of Raptor engines to exhaust its usefulness, the first orbital Starship prototype – and, even more so, the first Super Heavy booster – will almost certainly end up going through the same process of methodical hot-fire testing before SpaceX even thinks of attempting the first orbital BFR launch. Featuring 7 and 31 Raptors respectively, Starship and Super Heavy will radically push the envelope of both SpaceX’s own experience and the aerospace industry as a whole, potentially becoming the most powerful liquid rocket ever launched if or when the vehicle begins flight tests with both stages.

Quelle: TESLARATI

----

Update: 18.03.2019

.

Elon Musk shows off fiery SpaceX Starship heatshield test

Feeling hot, hot, hot.

SpaceX is on fire.

Figuratively speaking, of course. As if they've just dropped back-to-back-to-back buckets in a game of NBA Jam.

After successfully sending the first commercial crew capsule to the International Space Station in early March, Elon Musk's spaceflight company is on a hot streak and it's looking to continue that with an upcoming test launch of its much-discussed Starship.

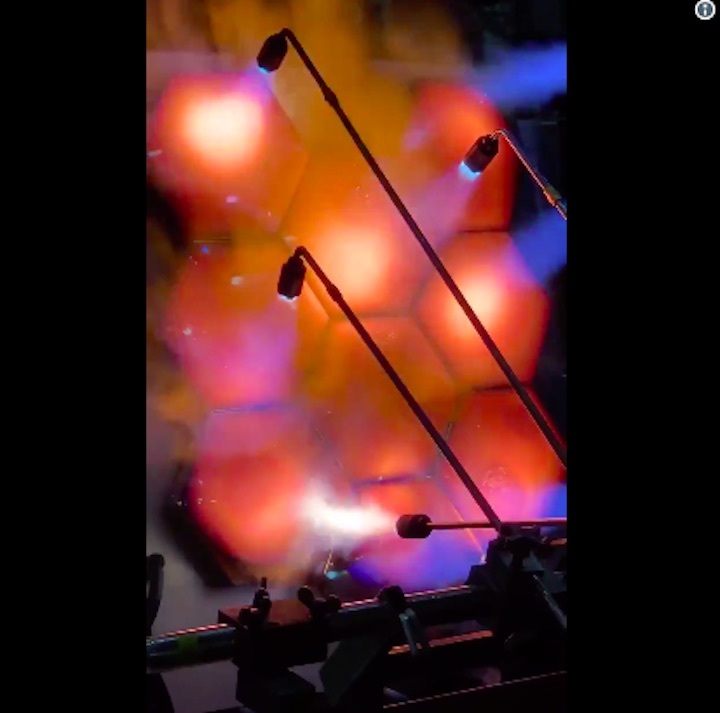

But before Starship gets off the ground, Musk has given spacefaring fans a glimpse of the hexagonal heatshield tiles that will eventually protect the craft from searing heat.

Testing Starship heatshield hex tiles

Musk explained that the hottest parts of the heatshield, glowing white in the short video above, reached a maximum temperature of around 1650 Kelvin (approx. 2,500 degrees Fahrenheit, approx. 1,375 degrees Celsius). He suggested this could withstand the extreme temperatures associated with returning to Earth, but it is slightly lower than the temperatures NASA's Space Shuttles were built to withstand (approx. 1,500 degrees Celsius).

On March 12, the Raptor rocket engine -- which will eventually help power Starship to the moon and beyond -- was spotted in Boca Chica, Texas, where SpaceX are gearing up for Starship's first test "hops". The hops will test the takeoff and landing capabilities of a Starship prototype, affectionately known as "Starhopper", and the Raptor engine.

On Friday, a Twitter user, Austin Barnard, snapped photos of the Raptor engine affixed to the Starhopper for the first time. With all of the machinery in place, Musk believes the test hops will take place within the coming week.

Quelle: Cnet

----

Update: 19.03.2019

.

SpaceX preparing to begin Starship hopper tests

THE WOODLANDS, Texas — SpaceX could begin initial tests of a prototype of the company’s next-generation Starship vehicle as soon as this week, Elon Musk said March 17.

In a series of tweets, Musk said flights of a “hopper” test vehicle, powered by a single Raptor engine, would “hopefully” begin this week pending work to integrate the engine, which arrived at the company’s South Texas test site late last week, with the vehicle.

Residents of a housing subdivision known as Boca Chica Village, near the test site on the Gulf of Mexico coast east of Brownsville, Texas, received a notice Friday from local officials informing them that the company could start testing “as soon as the week of March 18, 2019,” according to copies of the notice posted on social media. The notice said that a “safety zone” perimeter would be established for those tests, including checkpoints on the road leading from Brownsville past Boca Chica Village to the SpaceX site.

Asked on Twitter if the tests were in fact scheduled to begin this week, Musk replied, “Hopefully. Always many issues integrating engine & stage. First hops will lift off, but only barely.”

Past statements from Musk, as well as regulatory filings from the company, have indicated SpaceX plans to carry out an incremental test flight program using this vehicle, with very low altitude tests that, over time, will go higher and faster. Those tests will use a single Raptor engine, although Musk said later “suborbital” flights will be powered by three such engines.

Musk showed off development of the Starship prototype last December at the South Texas facility, planning at the time for test flights to begin in early 2019. SpaceX started testing of the flight version of the Raptor engine at its McGregor, Texas, engine test site in early February. Musk said then that the first Starship hopper flight would likely be in four to eight weeks.

Original plans called for the hopper to have a large nose cone, like that on the actual flight vehicle. That nose cone, though, was toppled in high winds at the South Texas site in January and suffered significant damage. Musk said in another March 17 tweet that the upcoming tests will not use a nose cone, since it’s not needed for the low-altitude flights planned. What’s being built now, he said, a future “orbital Starship” vehicle.

Starship is intended to be the reusable upper stage for the company’s next-generation launch system, with a separate booster called Super Heavy servicing as the reusable first stage. Development of Starship and Super Heavy are central to Musk’s long-term vision of enabling human settlement of Mars as soon as the 2020s.

The hopper vehicle is the first phase in the overall testing program for Starship and Super Heavy. “Once we get through the hopper test campaign, we’ll then be moving to orbital flight with Starship: getting up into Earth orbit and testing out systems on board and recovery,” said Paul Wooster of SpaceX during a March 17 presentation at the Microsymposium 60 here on commercial lunar lander systems. He didn’t estimate how long that hopper test campaign is expected to last.

SpaceX has plans to use Starship for lunar missions. The company announced in September it had signed up Japanese billionaire Yusaku Maezawa as the first customer for the system, then known as Big Falcon Rocket. Maezawa plans to fly a circumlunar trip around the moon on Starship as soon as 2023, along with a number of artists he plans to select as part of his “Dear Moon” project.

Starship is also designed to land on the moon. With the use of propellant transfer in Earth orbit, Starship will be able to land on the moon with up to 100 metric tons of cargo, Wooster said, depending on the amount of propellant loaded onto the vehicle. “We see it as a way to really help build up a base there,” he said of Starship’s role in lunar missions.

Quelle: SN

----

Update: 20.03.2019

.

SpaceX may begin testing its Starship spacecraft this week

"Starship needs to be ready to fly again immediately after landing."

For months in south Texas, SpaceX employees have been assembling a test version of the upper stage for its next-generation launch system. This prototype "Starship" is far from space-worthy, but it will allow the company to test the vehicle's ability to "hop" from the spaceport and then land propulsively back on the ground.

On Friday, the company sent a notice to nearby residents saying it planned to conduct testing of the vehicle as soon as the week of March 18, and that it would be closing the main roadway of Highway 4 to non-residents during the tests. This "safety zone perimeter" is part of an agreement with the local county, and has been set up out of an abundance of caution.

On Sunday, company founder Elon Musk confirmed on Twitter that SpaceX was indeed close to beginning tests. Musk said that integration work remained to be done on test vehicle and its Raptor rocket engine, and that the first hops would lift off, but only "barely." Eventually the "Starhopper" test vehicle will have three engines, but for now it appears as though the company will start with just one.

During something of a tweetstorm that was aggregated on the /r/spacex subreddit, Musk proceeded to share all manner of additional information about the test flights. (As we've previously noted, there are several reasons why Musk is sharing so much information about the development of Starship in south Texas).

Heat shield tests

Much of Musk's comments centered on the vehicle's heat shield, as SpaceX is attempting to design a spacecraft that can land on Earth through its thick atmosphere, and then take off again soon after. "Starship needs to be ready to fly again immediately after landing," Musk said. "Zero refurbishment."

The latest iteration of Starship's heat shield—and the design appears to change rapidly, as one might expect during the prototyping process—uses hexagon-shaped tiles. Musk then shared a video in which he said the tiles were heated to 1650 Kelvin (1375 degrees Celsius), adding that the overall heat shield used "Hexagonal tiles on most of windward side, no shield needed on leeward side, transpiration cooling on hotspots."

In terms of orbital flights, Musk said the company is seeking regulatory approval for launches from both the south Texas site near Boca Chica, as well as from the launch complexes at Cape Canaveral, Florida. SpaceX prefers to operate experimentally, at least from the Texas location, because it has autonomy over the site and does not need to coordinate with other launch providers.

As ever with the ultra-ambitious Starship and its companion Super Heavy rocket program, it is hard to know exactly how much progress is actually being made. But given that SpaceX now has a maturing Raptor rocket engine to power both stages and is nearing some semblance of flight tests, clearly the programs are moving forward. This is a testament to both the will of Musk, and the brilliance of his engineers.

Quelle: arsTechnica

+++

Elon Musk: SpaceX's next-gen Starship will be built in and launched from Florida

SpaceX's next-generation launch system designed to take humans beyond low-Earth orbit will at least partially call Florida home, CEO Elon Musk confirmed over the weekend.

When asked where the vehicle known as Starship and Super Heavy would launch from, Musk said both Texas and Florida would host liftoff and assembly operations.

"Working on regulatory approval for both Boca Chica, Texas, and Cape Kennedy, Florida," he said via Twitter Sunday. "Will also be building Starship and Super Heavy simultaneously in both locations."

Rocket manufacturing is a prestigious win for Florida, which historically has been designated as the launch site to which assembled vehicles were transported. SpaceX's Falcon 9 rocket, for example, is assembled in California, tested in Texas and moved via truck to Florida for spacecraft integration and launch.

Today, however, companies like Jeff Bezos' Blue Origin and now SpaceX are planning on building towering vehicles of aluminum and stainless steel right here on the Space Coast.

The future SpaceX vehicle comes in two parts: Super Heavy, a massive booster outfitted with 31 Raptor engines that will lift Starship, a 180-foot-tall spacecraft that can transport humans and cargo beyond low-Earth orbit. The latter has been likened to something out of science fiction thanks to its three-fin design and reflective, stainless steel outer shell.

A prototype of Starship, known as a "hopper," currently stands at SpaceX's test site in Texas, where engine tests are expected this week. If all goes according to plan, it will gently lift off on short "hops" that don't go as high as space, but high enough to test out systems and components.

Much like existing Falcon 9 rockets, Starship and Super Heavy will be reused to lower launch costs, decrease turnaround time and, if all goes according to Musk's plan, increase access to space. The first full test flight is targeted for no earlier than 2020.

At Kennedy Space Center, meanwhile, SpaceX teams are targeting the first half of April to launch the much-vaunted Falcon Heavy rocket on its first operational flight. On board will be Saudi Arabia's Arabsat 6A, a large communications satellite that will launch from pad 39A. It marks Falcon Heavy's first full mission since its wildly popular demonstration flight in February 2018.

Quelle: Florida Today

----

Update: 26.03.2019

.

Starhopper progressing toward Static Fire test; Starship/Superheavy updates

Testing of SpaceX’s Starhopper suborbital vehicle in Boca Chica, Texas, achieved a new milestone on Monday with another Wet Dress Rehearsal (WDR) and pre-burner test of the Raptor engine. This is another step towards engine ignition, which will technically result in its first hop, albeit by just inches due to being tethered to the pad.

Meanwhile, Elon Musk has presented new information on the overall Starship/Super Heavy design, including Starship’s heat shield and the fact that SpaceX is seeking regulatory approval to launch and build the massive interplanetary transport space vehicle in both Texas and “Cape Kennedy”, Florida.

(Lead image via “Nomadd” in the L2 Boca Chica section)

Starhopper testing:

SpaceX’s Starhopper is ramping up test operations at Boca Chica, Texas, ahead of what’s anticipated to an incremental series of testings, firings and hops.

In the past several days, observers at the east Texas test and launch facility have documented numerous cryogenic tests of Starhopper’s propellant tanks that hold Liquid Oxygen (LOX) and Liquid Methane to fuel the vehicle’s Raptor engines.

These tests involved fueling Starhopper with LOX and liquid methane and testing the pressurization systems, observed via icing of propellant lines leading to the vehicle and the venting of cryogenic boil off at the launch/test site.

These tanking and pressurization tests occurred after Starhopper was transported from its build location to its launch/test stand down the road and proceeded without any of the vehicle’s Raptor engines installed, something Elon Musk noted would happen in short order.

This was followed by visual confirmation last week of the first Raptor engine’s arrival at the Texas site and subsequent installation to Starhopper.

In quick order, residents of Boca Chica Village were notified via mail of imminent tests and road closures that would occur as early as this week, the week of 18 March.

The notice to residents revealed that a security checkpoint would be set up on the road leading to Boca Chica Village and that residents would have to show proof of residence in order to gain access to their homes; any passengers in those vehicles would also have to show proof of residence.

This indicates that no guests will be allowed past the security checkpoint during the coming flight test operations of Starhopper.

A hard checkpoint beyond which no access to Boca Chica Beach will be granted will be further down the road.

With the recent arrival and installation of the first Raptor engine into Starhopper, there was speculation as to whether the test Boca Chica residents were told of would be a hold down static fire or the first hop of Starhopper.

Elon Musk confirmed via Twitter at the weekend that it would “hopefully” be a hop – but only a barely getting off the ground hop and not a low-altitude suborbital hop.

Those suborbital hops require all three of Starhopper’s Raptor engines be installed.

This is quite a departure from how SpaceX has previously proceeded with vehicle testing – forgoing a hold down static fire and instead allowing the single Raptor to lift Starhopper off the ground – albeit only slightly – on its very first integrated firing.

In January, Mr. Musk indicated that Starhopper flight tests could begin as soon as February-March 2019 – which might come true – if no unforeseen circumstances occurred.

A significant storm impacted the Boca Chica test site earlier this year – knocking the top of Starhopper over and damaging it; it was thought that this would require a rebuild to the nose cone.

But Mr. Musk noted on Twitter (17 March) that the company is no longer building a nose cone for Starhopper – that they “don’t need it” – and that the additional construction seen at Boca Chica of late is actually for the first orbital Starship vehicle.

At least three WDRs have been conducted to date with at least one preburner test on the Raptor engine.

Starship design continues to evolve:

Meanwhile, as Starhopper continues toward its inaugural test at Boca Chica, Elon Musk spent some time answering questions on how the design of Starship continues to evolve, albeit not as drastically as it has before – a good signal that the design iteration phase is coming to completion as build operations begin.

Specifically, two intriguing and important pieces of information about Starship and Super Heavy were revealed by Mr. Musk at the weekend: 1) a heat shield will be used on the windward side of Starship and 2) SpaceX is seeking regulatory approval to launch and build Starship/Super Heavy in both Texas and Florida.

Per a Twitter post on 17 March 2019, Mr. Musk released a video of SpaceX testing the Starship heat shield hexagonal tiles that will blanket the windward side of the vehicle; these tiles will take the brunt of reentry heating.

Via the Twitter update, Mr. Musk noted that the tiles passed their testing with flying colors, reaching white-hot orbital entry temperatures of roughly 1650 Kelvin (1,377 ℃ – or 2,510 ℉).

Mr. Musk also revealed the hexagonal shape was chosen as it does not allow a straight path for hot gas to accelerate through any gaps in the heat shield – a critical component for reentry heating protection.

Furthermore, Musk reiterated that the leeward side of Starship will not require any heatshield at all thanks to its stainless steel construction and that any hot spots observed during testing will have transpiration cooling added to them.

Transpiration cooling is the act of pumping coolant – in this case, liquid methane – through the skin structure of Starship to absorb additional heat in particular areas of the vehicle during reentry.

Musk noted that these changes to Starship were needed to ensure that it could “fly again immediately after landing” with “zero refurbishment.”

As part of the Twitter update extravaganza, Mr. Musk also confirmed to NASASpaceflight’s Michael Baylor that SpaceX is working on regulatory approval to fly orbital missions of Starship from both Boca Chica, Texas, and “Cape Kennedy, Florida.”

He also confirmed that the company would build Starship and Super Heavy simultaneously in both locations, thus eliminating the need for lengthy transport of the huge vehicles from California.

Curiously, Elon’s use of “Cape Kennedy” nomenclature did not reveal whether Starship would be launching from the Cape Canaveral Air Force Station or from the Kennedy Space Center.

Quelle: NS